steel salt spray chamber|salt spray test chamber manufacturers : retailer Ascott salt spray test chambers – one of the world’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own. Chambers to cover every testing . Resultado da The latest tweets from @aroomikim

{plog:ftitle_list}

web14 de dez. de 2019 · Qual o MELHOR ANIMATRONIC DE FNAF? Torneio FNAF. Core. 345K views. Explicando a Speedrun de FNAF. Save Manual. 809K views. Explaining EVERY Easter Egg! - FNAF .

Explore the essential role of salt spray chambers in corrosion testing, featuring the ASTM B117, ASTM G85, and more. Discover how Pacorr's innovative solutions lead the industry.What is salt spray testing? A salt spray test is a corrosion testing method that uses high-saline environments to measure the corrosion resistance of products, paints, and coatings over extended periods. This accelerated process applies .Corrosion Test Chambers Testing climate resistance to the limit STANDARD: ISO 9227-2017(E) Salt Spray Method Statement EQUIPMENT: All Ascott Corrosion Chambers 1. Scope 1.1 This methodology is to be used to perform the ISO 9227-2017(E) Salt Spray test standard in an Ascott corrosion chamber. This should be used in conjunction with the ISO 9227-Ascott salt spray test chambers – one of the world’s most modern and most versatile salt spray corrosion test systems – and with design, ergonomics and quality that’s in a class of its own. Chambers to cover every testing .

The most common test for steel based materials is the Neutral Salt Spray test (often abbreviated to NSS) which reflects the fact that this type of test solution is prepared to a neutral pH of 6.5 to 7.2. . Our durable salt spray testing chambers can test a number of test specimens of many sizes, shapes and dimensions for the ASTM B117 Salt .ASTM B117 salt fog or salt spray test is a common corrosion test designed to provide corrosion. . (nickel-chromium) on steel, zinc die castings, or cadmium plate on steel. Instead, it is suggested to opt for ASTM B368 or Practice G85, which are test standards specifically designed for assessing corrosion resistance in these materials .for salt fog testing, except that the absence of salt slows down the reaction. • Acetic Acid /Salt Spray (ASTM B287): This test is applicable to. painted and plated coatings over steel substrates. It will typically yield faster results than neutral spray due to acid attack (pH 3.1 -3.3). Coating Hard chromium Decorative chromium ASTM B117 is a document that establishes operating parameters and requirements for salt spray test chambers. It details how to create and maintain a salt spray test environment so that consistent results can be obtained from room to room in different laboratories.

This professional Salt Spray Chamber is designed and engineered offering the newest microchip technology combined with Analog Controls or a large Color Touchscreen Display, a homogeneous Salt Fog Distribution across all samples, a transparent Lid for sample monitoring, advanced Heating System with Infrared Temperature Monitoring, a high-speed . Salt Spray Test Chamber and Equipment: The salt spray test offers several advantages to industries that rely on corrosion-resistant materials. This section explores the benefits of salt spray testing from different perspectives, including product development, quality control, and customer satisfaction. .metals exposed in a given test chamber. 3.2 Prediction of performance in natural environments has seldom been correlated with salt spray results when used as stand alone data. 3.2.1 Correlation and extrapolation of corrosion perfor-mance based on exposure to the test environment provided by this practice are not always predictable.

EIS to study the corrosion behavior of carbon steel in salt spray chamber, and found that the corrosion rate in salt spray environment was five times that in 5% NaCl solution. The above research results once again prove that the corrosion process of low carbon steel in salt spray chamber is different from that in other envi-ronments.The four PM stainless steel materials selected for this preliminary exercise were: 1. SS-316N1 2. SS-316N2 3. SS-316H 4. SS-434 (processed in the manner of an “H” grade material) . Figure 5: Schematic of salt spray chamber – from ASTM B117. Figure 6: TRS bars in their racks prior to salt spray testing. Table 6: .Salt spray tests are also often combined with other corrosion test methods to perform so-called corrosion cycling tests. Among the features of the RSI corrosion test chests are – Structure in accordance with DIN EN ISO 9227, DIN EN 60068-2-11, ASTM B117. – Test chamber material: Polypropylene or special stainless steel materials

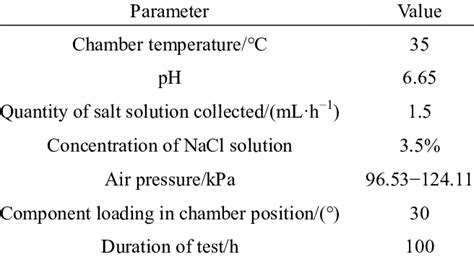

The weight-loss test was conducted by using a salt spray chamber. The samples for mass variation measurements were placed in the salt spray chamber. Atomized NaCl solution was sprayed on the surface of samples. The temperature in the salt spray chamber is 35°C, and the atomization pressure of NaCl solution is 0.093 MPa. Working in the salt spray chamber The metal used in manufacturing is often subjected to extremes of temperature and humidity and chemical vapors that may lead to corrosion. Therefore, it is essential to conduct tests on the materials to evaluate their quality. The triple wall construction of LISUN’s salt chamber guarantees a complete lack of heat transfer . Stainless steel 316L is taken in the form of the sheet of size 320*160*3 mm. In the sample of stainless steel 316L, salt spray test was performed. In salt spray test chamber, a standard solution of 5% NaCl (sodium chloride) is used to create a highly corrosive atmosphere. The salt spray chamber continuously sprays the salt solution as a fine mist (or fog) throughout the test, ensuring that the specimen is constantly exposed to the salt-laden air. 3. Starting the Test

salt spray test chamber price

Find Salt Spray Test Chamber manufacturers, suppliers, dealers & latest prices from top companies in India. Buy from a wide range of Salt Spray Test Chamber online. . Stainless Steel Salt Spray Test Chamber. Price : 600000 INR. View More Products from KASCO INDUSTRIES PRIVATE LIMITED. Call Now View Number Send Inquiry WhatsApp. Salt Spray Chamber Ventilation. To prevent back pressure within the chamber, it must be exhausted. When setting up the chamber, be sure to install a non-corrosive three-quarter-inch pipe from the exhaust chamber to a point outside the building. This exhaust should be as short as possible, straight, and gently sloping downward from the chamber . The salt spray test is an accelerated laboratory test that provides a controlled corrosive environment to determine the corrosion resistance of stainless steel. The test exposes components to a salt spray (fog) solution of 5 percent sodium chloride in a test chamber heated to 35 degrees C. Although the test duration is short compared with the .The Atlas SF Series are rugged and reliable chambers for traditional Salt fog (spray) and Humidity Testing. SF cabinets are used to quickly qualify a coating or material on a pass-fail basis, or determine the probability of corrosion of a specific material. . Durable steel cabinet with 55 gal (208 L) solution reservoir with mixing system on .

Business listings of Salt Spray Chambers, Salt Spray Test Chamber manufacturers, suppliers and exporters in Delhi, साल्ट स्प्रे चैम्बर विक्रेता, दिल्ली, Delhi along with their contact details & address. . Mild Steel Salt Spray Chamber ₹ 40,000 Get Latest Price . Material: Mild .

The test begins by placing the sample or coated object in a specially designed salt spray cabinet chamber. The cabinet is then filled with a solution comprising mainly sodium chloride (NaCl), which resembles natural seawater. . For example, stainless steel or aluminum typically exhibits better corrosion resistance than plain carbon steel .

The MX Series is c ompletely self-contained; the MX Series salt spray chambers enable test items to be subjected to a corrosive environment without introducing other contaminants into the test area, making the DUT visible from almost any angle. This corrosion-mimicking process is observable, again, through 360-degree high-quality Lucite®️ plexiglass.Steel Salt Spray Testing Machine Salt Spray Test Chamber Video salt spray test chamber brochure. Specifications. Salt Spray Testing Machine 2, Durable hard PVC construction 3, Short delivery and best service 4, Durable and easy operation. Salt Spray Testing Machine. Description: The Salt Spray Testing Machine is a standardized test method used to check .

Product Description: Qualtech Products Industry Salt Spray Test Chamber is a professional Advanced Automatic Accelerated Corrosion Test Chamber to evaluate the Corrosion Resistance of surface materials, surface coatings and protective films at the touch of a button. This Advanced Weathering Salt Spray Test Chamber integrates many advanced and new features to elevate .The most common test for steel based materials is the Neutral Salt Spray test (often abbreviated to NSS) which reflects the fact that this type of test solution is prepared to a neutral pH of 6.5 to 7.2. . Our durable salt spray testing chambers can test a number of test specimens of many sizes, shapes and dimensions for the ASTM B117 Salt .

volkswagen diesel compression tester

salt spray test chamber manufacturers

Resultado da See MartinaOlvr's porn videos and official profile, only on Pornhub. Check out the best videos, photos, gifs and playlists from amateur model MartinaOlvr. .

steel salt spray chamber|salt spray test chamber manufacturers